Throttle control systems are fundamental to the efficient operation of modern engines, whether in vehicles, industrial machinery, or marine applications. Among the various systems available, the K25LP throttle control has emerged as a standout solution, known for its precision, reliability, and versatility. This blog post delves into the intricacies of the K25LP throttle, exploring its features, operational mechanics, benefits, and applications.

What is K25LP Throttle Control?

The K25LP throttle is an electronic throttle control (ETC) system designed to manage the air-fuel mixture entering the engine. This control unit regulates engine speed, enhances performance, and improves fuel efficiency. By integrating advanced technology, the K25LP throttle control offers significant advantages over traditional mechanical throttle systems, making it an essential component in various applications.

Key Features of K25LP Throttle

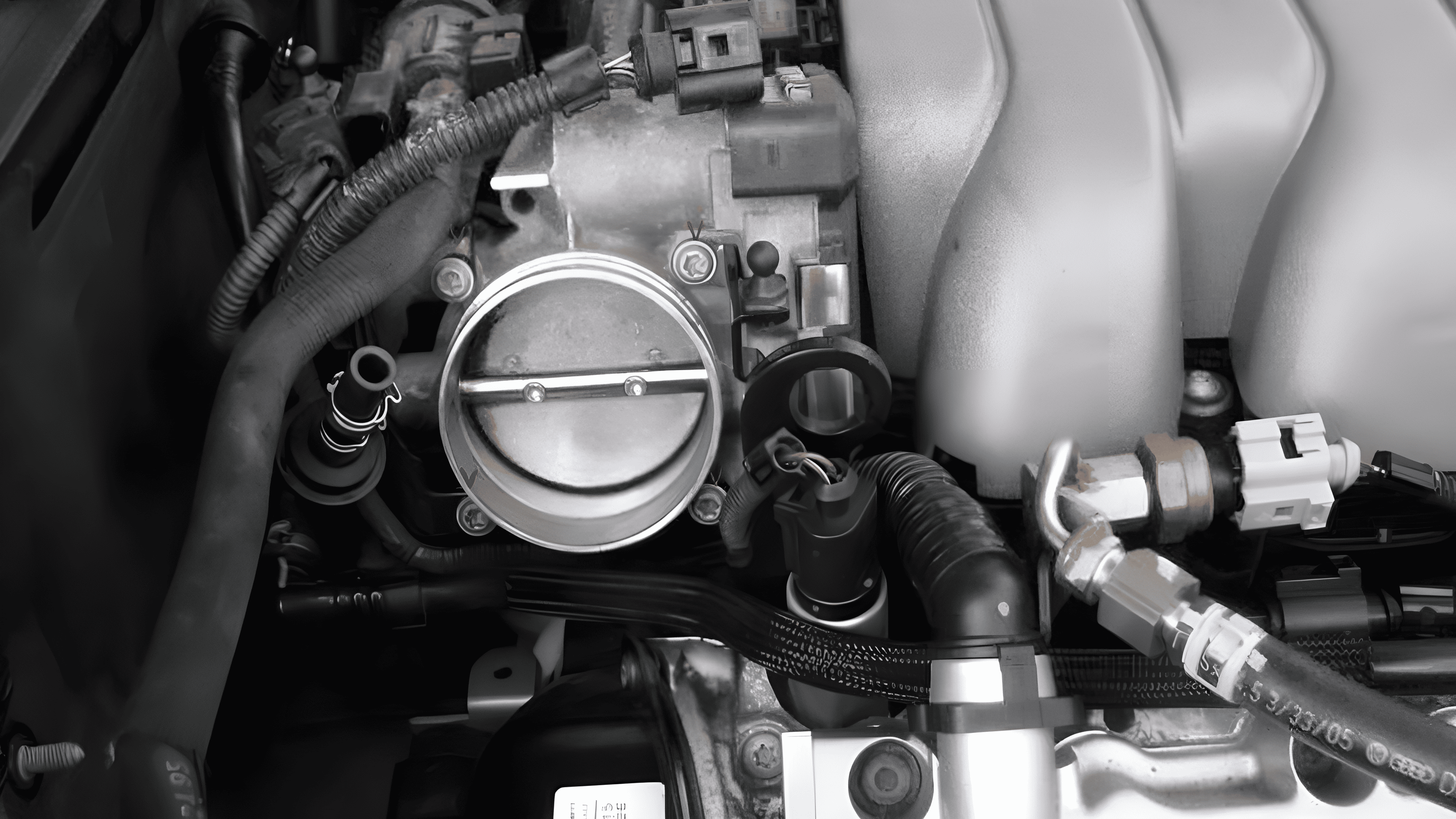

1. Advanced Electronic Control

The K25LP throttle employs electronic components to monitor and adjust throttle positions. Unlike mechanical systems, which rely on cables and levers, the K25LP uses sensors and actuators to achieve precise throttle management. This electronic control ensures faster response times and improved accuracy, which are crucial for optimal engine performance.

2. Durable Construction

One of the defining features of the K25LP throttle control is its robust construction. Made from high-quality materials, this control unit is designed to withstand harsh operating environments. Its durability minimizes the risk of failure, reducing maintenance costs and downtime, making it an ideal choice for industrial and automotive applications.

3. User-Friendly Interface

Many K25LP throttle systems come equipped with intuitive user interfaces. These interfaces allow operators to easily monitor and adjust throttle settings, enhancing usability and control over engine performance. The user-friendly design contributes to smoother operations, particularly in complex machinery where precise throttle management is crucial.

4. Versatile Applications

The K25LP throttle can be integrated into various systems, from automotive engines to industrial machinery and marine applications. Its versatility makes it a go-to solution for different sectors requiring efficient engine management. This adaptability is a significant advantage in industries where specific performance criteria must be met.

How Does K25LP Throttle Control Work?

Understanding how the K25LP throttle functions requires a closer look at its operational mechanics. Here’s a step-by-step breakdown of the process:

Step 1: Signal Acquisition

The K25LP throttle control system begins by receiving signals from various sensors. These sensors can include:

- Accelerator Pedal Position Sensors: These sensors detect how far the accelerator pedal is pressed, translating the driver’s intentions into electrical signals.

- Engine Load Sensors: These sensors measure the load on the engine, providing real-time data to the throttle control system.

Step 2: Throttle Position Adjustment

Based on the input signals received, the K25LP throttle calculates the optimal throttle position. The electronic control unit (ECU) interprets these signals and sends commands to the electronic actuator, which opens or closes the throttle plate accordingly.

Step 3: Engine Response

As the throttle position changes, the engine responds by adjusting its power output. A wide-open throttle allows more air and fuel into the engine, increasing power, while a closed throttle reduces power. This dynamic adjustment is vital for maintaining the desired speed and performance in various driving conditions.

Step 4: Continuous Feedback Loop

The K25LP throttle system operates within a continuous feedback loop. Sensors constantly monitor the throttle position and engine performance, providing real-time data to the ECU. This feedback allows for rapid adjustments to ensure that the engine operates efficiently and effectively, adapting to changing conditions seamlessly.

Benefits of Using K25LP Throttle

The K25LP throttle offers numerous advantages over traditional mechanical systems.

1. Improved Fuel Efficiency

One of the most significant advantages of the K25LP throttle control is its ability to enhance fuel efficiency. By optimizing the air-fuel mixture and adjusting throttle positions precisely, the K25LP helps reduce fuel consumption, leading to cost savings and a lower environmental impact.

2. Enhanced Performance

With precise throttle management, the K25LP enables better engine response and acceleration. This enhancement translates to a more enjoyable driving experience and improved overall performance, particularly in high-demand situations like towing or heavy loads.

3. Lower Emissions

The K25LP throttle contributes to reduced emissions by ensuring that the engine runs efficiently. With optimized air-fuel mixtures and improved combustion processes, the K25LP helps vehicles and machinery meet stringent environmental regulations.

4. Increased Reliability

The durability and robust construction of the K25LP throttle control reduce the likelihood of failures. This reliability is crucial in both automotive and industrial applications, where downtime can lead to significant operational losses. With fewer mechanical components, the K25LP also minimizes wear and tear, contributing to its longevity.

5. Safety Enhancements

Modern throttle control systems like the K25LP often include safety features that can prevent unintended acceleration or other issues. These safety mechanisms enhance the overall safety of the vehicle or machinery, providing peace of mind for operators and users.

Applications of K25LP Throttle Control

The versatility of the K25LP throttle makes it suitable for a wide range of applications across various industries:

1. Automotive Industry

In the automotive sector, the K25LP throttle is widely used in modern vehicles. It is a crucial component of electronic throttle control systems, providing precise management of engine power and efficiency. This technology has become standard in many new vehicles, improving performance and fuel economy.

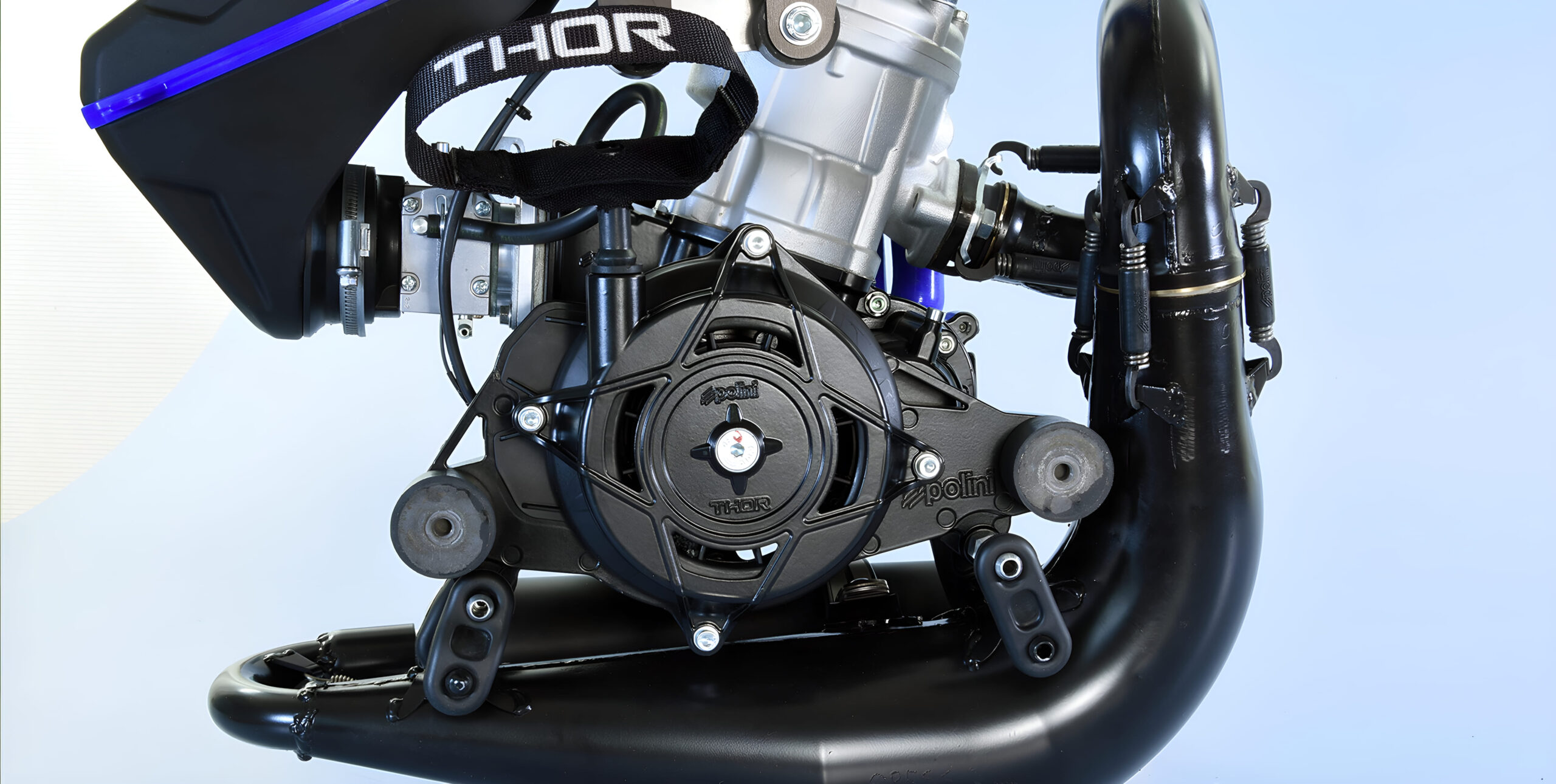

2. Industrial Machinery

Many industrial machines, including forklifts, generators, and agricultural equipment, utilize the K25LP throttle control for efficient engine management. In these applications, precise throttle control can significantly enhance productivity and operational efficiency.

3. Marine Applications

In marine engines, accurate throttle control is essential for managing speed and fuel consumption. The K25LP throttle can be employed in various marine applications, ensuring optimal performance while navigating through different water conditions.

4. Aerospace

In aerospace applications, throttle control must be highly reliable and responsive. The K25LP throttle can be utilized in specific aerospace engines, contributing to flight safety and performance.

5. Heavy Equipment

Construction and heavy machinery often rely on throttle control systems to manage engine power efficiently. The K25LP’s robust design and adaptability make it an ideal choice for equipment like excavators, bulldozers, and cranes.

Challenges and Considerations

While the K25LP throttle offers many benefits, there are also challenges and considerations to keep in mind:

1. Complex Integration

Integrating the K25LP throttle control into existing systems can be complex, especially in older machinery or vehicles. It may require additional components and adjustments to ensure compatibility and optimal performance.

2. Initial Costs

The initial investment for implementing advanced throttle control systems like the K25LP may be higher than traditional mechanical systems. However, the long-term savings in fuel efficiency and reduced maintenance costs can offset this initial expense.

3. Technical Knowledge Requirement

Operating and maintaining systems with K25LP throttle may require specialized knowledge. Training for operators and maintenance personnel can be necessary to ensure effective usage and troubleshooting.

Future of K25LP Throttle Control

As technology continues to advance, the future of throttle control systems like the K25LP looks promising. Ongoing developments in sensor technology, artificial intelligence, and machine learning could further enhance the capabilities of throttle control systems. Potential future trends may include:

1. Integration with Autonomous Systems

With the rise of autonomous vehicles and machinery, throttle control systems will need to evolve to integrate seamlessly with advanced driver-assistance systems (ADAS). The K25LP throttle could play a crucial role in ensuring that these systems operate safely and efficiently.

2. Enhanced Connectivity

The increasing demand for connected devices means that future throttle control systems may offer enhanced connectivity options. This connectivity could allow for real-time monitoring and diagnostics, further improving performance and reliability.

3. Sustainability Focus

As industries push for more sustainable practices, throttle control systems like the K25LP will likely continue to evolve to meet these demands. Enhanced fuel efficiency and reduced emissions will remain key objectives in the development of future throttle control technologies.

Conclusion

The K25LP throttle control is a vital component in modern engine management systems, offering a range of benefits that enhance performance, fuel efficiency, and safety. Its advanced electronic control, durability, and versatility make it an ideal choice for various applications, from automotive to industrial and marine uses. As technology continues to advance, the K25LP throttle is poised to play an increasingly significant role in optimizing engine performance and meeting the evolving demands of various industries.